UK fire and rescue services attend over 300 significant fires in waste sites each year. These fires come with an annual cost to fire and emergency services of £16million

HIGH RISK MATERIALS CAUSE FIRES

Used batteries

Gas Cylinder

Solvents

Waste Paper

Organic Waste

Why Use Thermal Cameras for Fire Prevention?

Non-Contact

Non-contact temperature measurement wont affect the normal operation of the monitored target

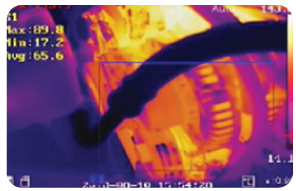

Visualized

Visualised temperature measurement, helps double check problems and improve problem solving efficiency

Early-Warning

Monitoring temperature change and triggering pre alarm before the fire occurs helps protect the property.

Smart Flexible

Measurement rules & high temperature/low temperature/temperature difference alarms.

24/7 Monitoring

Day & night 24/7 continuous monitoring, real time alarm notification

TEMPERATURE MEASUREMENT FUNCTION

High Accuracy

The accuracy is highly ensured, reaching max (±2°C or ±2%, -20 to 550°C) for thermography product and (±8°C, -20 to 150°C) for security product. Temperature difference fluctuation is small, and stability is satisfactory.

Flexible Rules

Support accurate temperature measurement rules such as points, lines, and frames. Flexible rules meet the requirement of thermography of key areas and special points, which hugely increases effectiveness. With 10 areas, 10 points and 1 line.

Colour Highlight – Isotherm

Set highlight colour for temperature in a user-defined range, to quickly locate areas with specific temperature

FALSE ALARM FILTER

The heat that is generated by a vehicle engine, can be over the pre-set temperature threshold in your monitor area. So when the vehicle passes through the area, a false alarm could be triggered.

With the help of AI algorithm, thermal cameras have been trained to recognise and ignore the heat from the vehicle engine

Multi-dimensional temperature algorithm reduces the unwanted high temperature alarms caused by sunlight reflection.

HIGH RISK MATERIALS CAUSE FIRES

Landfill site in Slovenia use thermal

cameras to detect fire in waste dumps

Recycling plant in Spain uses thermal

cameras to detect fire in waste dumps

INTRODUCING PROTHERMAL CUBE CAMERA

Thermographic cube cameras are suitable for scenarios that require accurate temperature measurement in narrow space or short distance. Customers may also benefit from temperature data as well as thermal image.

Electrical Cabinet

Data Centre

Manufacturing Process Control

Industrial Core Facilities

WHY TEMPERATURE SENSING IS REQUIRED

Undetected overheats, caused by electrical connectors, faulty battery charger etc. can all lead to fires. While there are many devices to detect a fire, our solution, while not designed to replace a traditional fire alarm system, will give you warning before the fire starts.

ProThermal Cube cameras can be placed inside of electrical cabinets, data cabinets or strategical positions to look at individual process controls, valves, transformers battery chargers etc.

WHY CONSIDER PROTHERMAL

- Easy installation can sit on customers existing data infrastructure

- Wide Field of View, for monitoring narrow spaces

- Wide temperature measurement range & high temperature measurement accuracy

- Bi-spectrum image fusion, which shows more image details.

- Provides warning before fire starts

- Competitive price