Proline linear heat detection provides early warning of fire or overheating equipment. Heat sensing cables are capable of detecting heat anywhere along their length and are designed for use in commercial and industrial applications. Linear heat detection is a highly cost effective and can be easily installed with, or in place of, conventional heat detectors where traditional style detection may be difficult to install, maintain or is too expensive.

HOW DOES LINEAR HEAT DETECTION WORK?

There are two types of heat sensing cable available, fixed temperature and analogue:

INDUSTRIAL SERVICES

ProLine linear heat detection is well suited to a wide range of applications, including:

The main cause of fires in cable trays is due to overheating cables caused by over voltage, short circuit, etc. Cable trays generally consist of a number of cables running side by side tightly packed together. Development of a fire in a single cable can very rapidly spread to other cables due to the close proximity, causing severe consequential losses.Generally cable trays are located in restricted spaces (service tunnels/vertical risers) making access difficult and potentially leading to undetected fire spread therefore early detection of an overheat condition is necessary to prevent a major disaster.

Proline is ideally suited to this type of application as it can be installed very close to the point of risk giving the earliest possible detection of an overheat condition. Proline is unaffected by the environmental conditions which may cause false alarms with other detection types i.e. dust, humidity etc.

Design and installation guidelines

Depending on the configuration of the cable trays or racks, i.e. whether it is a single run or multiple levels of cable trays, it would generally be necessary to split the cable trays into smaller detection zones making identification of the overheat location easier. Zoning can be configured in relation to:

- Physical barriers

- Defined sections of cable tray or rack

- Existing extinguishing zones

The interface used for monitoring Proline may be located in the detection zone or remotely, the latter requiring an interposing cable from the interface to the detection zone, connected to Proline via a suitable junction box and fire rated cable.

Proline must be supported at a maximum of one meter spacing and should be installed no more than 200mm above each cable tray/rack. This provides maximum operating sensitivity without obstructing access to the cables. A further run of Proline is recommended on the underside of the bottom tray/rack to protect against any ‘debris’ fire.

- A single run of Proline will cover a cable tray <600mm wide

- Cable trays >600mm wide will require additional runs of Proline

The width of the cable trays will be significant in determining the amount of Proline required to provide the best detection.

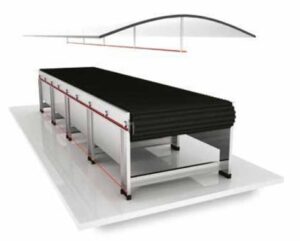

Conveyor fires are most commonly caused by friction. This occurs when the roller bearings used to move the conveyor belt seize and the rubber conveyor belt rubs against the seized bearing causing an overheat condition. This overheat if not detected early can cause ignition of the fuel being carried on the conveyor, the conveyor belt and other adjacent combustibles.

A fire generated by friction, which if allowed to spread can cause severe damage to the belt, and the housing containing the conveyor. Proline can be used to provide point of risk detection to give an early warning of an overheat condition. Interfacing with other control equipment can initiate conveyor shut downs and operation of suppression systems to prevent the spread of a fire.

Proline is particularly suitable as it can be installed where high levels of dirt, dust, wind and moisture exist and still be effective. The design of the conveyor will determine which type of cable to use, but where exposed to the elements mechanical and chemical protection may be required.

Design and installation guidelines

The recommended design is to install Proline down each side of the conveyor clipped to the roller supports to detect an overheat on the bearings, with a further run under the bed plate on each side to detect overheat fires caused by the spillage of product from the conveyor belt.

If the conveyor is enclosed or covered then it would be recommended to install Proline above the conveyor belt to detect any fires on a stationary conveyor belt. Other areas of conveyors which should also be considered for the use of Proline would be the drive motors and oil filled gear boxes.

Suitable Fixing Accessories

Dual Height L Clip (A1164/A1165) Standard L Clip (A1166/A1167) L Clip (200mm) (A1168/A1169)

Multi-storey and underground car parks have always been vulnerable to fire.

The combustible materials used in the manufacture of modern passenger vehicles results in fires that burn more intensely and generate higher temperatures than ever before with the opportunity for fire spread significant.

Detection systems in car parks are often subjected to the elements and possibly vandalism.

Proline is prevalent for this type of application as it can be installed in environments where wind, dust and moisture are present; which can commonly lead to false alarms for other detection types.

Proline if installed correctly is unaffected by temperature variations caused by seasonal weather conditions and provides a discrete form of detection.

Design and installation guidelines

In this application, Proline provides area protection as opposed to point of risk therefore the design shall follow the guidelines for normal point type heat detectors regarding maximum spacing between cable runs and zone size.

Due to the flexibility of Proline, it can be run in any location to provide the best coverage to ensure all vehicles are adequately protected.

It is recommended in this application that nylon coated Proline is used, which will provide protection against the elements as well as hydrocarbons from exhaust fumes.

Dual Height L Clip (A1164/A1165) Standard L Clip (A1166/A1167) L Clip (200mm) (A1168/A1169)

Channel Bracket (A1172/A1173)

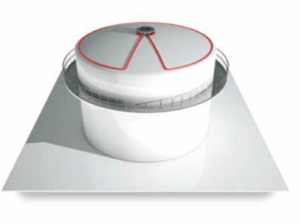

Floating roof tanks are most commonly used for storing highly flammable products making them a potential catastrophic fire risk. The main risk of fire is from the ignition of vapour escaping from a damaged/worn rim seal. It is essential that fires are detected at the earliest possible opportunity to prevent a widespread fire and activate suitable fire suppression systems.

With a range of high temperature chemical resistance cable, Proline offers the most cost effective and reliable method for rim seal fire protection, it is easy to install close to the rim seal.

Installation of ATEX approved junction boxes and intrinsically safe barriers/isolators between Proline and the interface unit provides the necessary protection for hazardous areas.

Design and installation guidelines

The design of each floating roof tank can differ greatly dependent on the manufacturer therefore we recommend close liaison with the end user/site owner during the installation and design phases.

Where possible the recommendation would be to use edge clips on the foam dam with

a distance piece to position the Proline cable between the dam and the outer wall of the tank close to the rim seal. Proline

should be supported every metre around the circumference of the rim seal. A suitable ATEX approved junction box will be provided on the roof top for termination of Proline

To connect Proline back to the control unit electrical connections between the tank top and rim are made using either an automatic cable reeler, or a cable collector with retractable cables to accommodate the rise and fall of the tank roof. The interface unit being used to monitor Proline will be located in a non-hazardous area and to maintain the safety of the system Proline connections to the control unit will be connected through suitable intrinsically safe barriers/isolators.

Dual Height L Clip (A1164/A1165) Standard L Clip (A1166/A1167) L Clip (200mm) (A1168/A1169)

The construction layout of tank farms often results in tanks containing highly flammable material that are in close proximity to each other. This makes them a considerable fire risk with a significant threat of a fire spreading between tanks.

Proline can be installed on the tanks and in close proximity to monitor the vents, flanges, gauging points, manholes, and general bund areas for fire. The system can be linked into a main fire system to trigger activation of a deluge water spray/foam system.

Design and installation guidelines

The recommended installation of each tank will vary based on the physical design, but each tank will generally be protected by one continuous zone of Proline.

Proline will be terminated in a suitably certified junction box with interposing fire rated cabling and connected to the control unit, located in a safe area. As the tanks will be located in a hazardous area the cable should be connected to the control unit via approved intrinsically safe barriers/isolators.

To connect Proline back to the control unit electrical connections between the tank top and rim are made using either an automatic cable reeler, or a cable collector with retractable cables to accommodate the rise and fall of the tank roof. The interface unit being used to monitor Proline will be located in a non-hazardous area and to maintain the safety of the system Proline connections to the control unit will be connected through suitable intrinsically safe barriers/isolators.

Dual Height L Clip (A1164/A1165) Standard L Clip (A1166/A1167) L Clip (200mm) (A1168/A1169)

Fires in densely packed racking can be detected with a localised Proline detection system. Proline can be installed within the racking to provide detection very close to the point of risk, providing a discrete detection system which is unaffected by the normal working environment.

Proline can be zoned within the racking and is often used to trigger the pre-action stage of a sprinkler system to ensure rapid detection and control of the spread of fire.

Design and installation guidelines

The recommendation is to install Proline at the ceiling and within the rack, fixing it to the existing shelf supports in a position where it will not be damaged when loading and unloading the shelves.

The warehouse and racking can be split into zones to reduce the search area and to activate the relevant sprinkler/suppression system.

The interface used for monitoring Proline may be located in the detection zone or it may be installed remotely. If the interface is to be located remotely an interposing cable from the interface to the detection zone is required, this is connected to Proline using a suitable junction box and fire rated cable.

Freezer warehouses

Where a warehouse is used for cold storage and operates at low temperatures Proline can be used to provide general area protection. The design follows the guidelines for point type heat detectors or installed as ‘in-rack’ protection. The following specialist recommendations should be noted:

- Nylon coated cable should be used

- Minimum operating temperature:

- Minimum installation temperature -11°C

- Interface units must be installed in areas with an ambient temperature above 0°C

Dual Height L Clip (A1164/A1165)

Standard L Clip (A1166/A1167)

L Clip (200mm) (A1168/A1169

Channel Bracket (A1172/A1173)

ESCALATORS AND TRAVELATORS

Fires on escalators and travelators can develop rapidly into a major fire and can spread because of the continued mechanical movement. The public nature of this application means that it is crucial to have the earliest possible detection system to initiate emergency procedures.

Proline can be installed at the point of risk,

and can protect the following potential fire risks:

- Drive motors

- Roller bearings

- Truss rollers

- Dust collector trays

Due to the movement of mechanical parts it would be recommended that Proline should have mechanical protection; chemical

protection should also be considered due to the presence of oil and grease.

Design and installation guidelines

Proline can be used to protect the roller trusses and any other moving parts for risk of overheat due to friction. Proline should be installed on both sides of the escalator to protect the rollers, and at the top and bottom of the escalator to detect potential fires in the dust collection trays.

Where necessary the escalator or travelator can be split into smaller detection zones. If the Proline system is to be used in conjunction with a suppression system it may be necessary to install two independent systems to provide coincidence operation.

Care should be taken when attaching the Proline to the roller bearings to ensure that it is not damaged by the moving treads of the unit. The interface used for monitoring Proline may be located in the detection zone or it may be installed remotely. If the interface is to be located remotely an interposing cable from the interface to the detection zone is required, this is then connected to Proline using a suitable junction box and fire rated cable.

Dual Height L Clip (A1164/A1165)

Standard L Clip (A1166/A1167)

L Clip (200mm) (A1168/A1169)

Channel Bracket (A1172/A1173)

Tunnels pose a challenging fire threat due to their confined structure. Tunnels primarily offer limited access/egress points, making it crucial that fires are detected at the earliest opportunity to enable evacuation and extinguishing of the fire.

Proline detection offers a cost effective solution that can provide protection for all the different facets of the tunnel system, with design capabilities to be compatible with the other tunnel operating systems.

There are many different potential hazards within the tunnel environment such as electrical services, motor vehicle accidents, vehicle load fires, vehicle fires, fuel fires, etc..

Design and installation guidelines

Specific electrical risks can be protected by installing Proline at the point of risk. The biggest risk is vehicle fires which can cause significant problems including intense heat and thick black toxic smoke making access and egress difficult.

To detect vehicle or fuel fires we would provide a general area type protection with Proline installed directly over the roadways inside the tunnel. Proline can be split into separate zones depending on the width and length of the tunnel. Detection zones could be linked to suppression systems for localised fire fighting or ventilation zones to activate extraction systems.

Proline can also be used to detect fires in sumps and drains designed for containment of fuel or oil spills. These systems can be linked to a foam suppression system to provide extinguishing of any fire. Due to the environmental conditions Proline installed within tunnels should have a nylon coating.

The interface used for monitoring Proline may be located in the detection zone or it may be installed remotely.

If the interface is to be located remotely an interposing cable from the interface to the detection zone is required, this is connected to Proline using a suitable junction box and should be a suitably fire rated cable where possible.

Dual Height L Clip (A1164/A1165)

Standard L Clip (A1166/A1167)

L Clip (200mm) (A1168/A1169

Channel Bracket (A1172/A1173)